Unlike other range cookers, the Alpha is not the “heat store” type as only limited heat is emitted. It is also completely programmable, therefore it can be switched off when you have finished cooking, a welcome bonus in those hot summer months!

Alpha Cookers has been established since 1995. The founders of Alpha Cookers (UK) Ltd. started in the range cooker refurbishment industry over twenty years ago and utilised this wealth of experience to design and develop their own cast iron range central heating system.

From the outset, the company’s guiding principles have been to apply traditional materials and manufacturing processes to utilise the latest technology in producing a cooker which is both the focal point of the kitchen and the powerhouse of the central heating system.

Alpha Cookers obtain castings from a local foundry in Oxfordshire and are proud that all of their models are ‘hand made in Great Britain’.

Both ovens and hotplate work together. Your hotplate will take approximately 10 minutes to heat through and will vary in temperature depending on which area of the hotplate you use.

When your hotplate is in use, the hot plate lids may remain open. The temperature will stay constant as the burners in the Alpha will ‘top up’ as required.

The ovens will reach temperature within 25-30 minutes when the dial is set to 200ºC. The bottom oven is 60% of the temperature of the top oven.

For Example:

Top Oven

220ºC at the top of this oven

200ºC in the middle

180ºC on the bottom of this oven

Bottom Oven

130ºC

Oven Dimensions (same for top and bottom oven)

Deep: 48cm – 19″

Wide: 40cm – 15 3/4″

High: 33cm – 13″

This means that the Alpha is very versatile.

The top oven is ideal for slow cooking and easily adjusted by simply setting the temperature to approximately 140ºC.

Please note 140ºC in the top oven will make the temperature in your bottom oven 84ºC.

Cleaning the Alpha

To clean the ovens set the oven control stat to 250ºC for 30 to 40 minutes then turn off and allow to cool. Once the oven is cool all you have to do is vacuum inside the ovens!!

Exterior cleaning of the Alpha may only be done when unit is cold or just warm to touch. You can use warm soapy water or ‘Astonish’ cleaner which can be purchased through us.

Hotplates must be kept clean to ensure good operation

The Alpha Oil central heating model will run up to 160,000 BTU output.

The Alpha Gas central heating model will run up to 120,000 BTU output.

Fully pumped and vented or sealed but not gravity.

It is also well adapted for under floor heating.

Cleaning the Alpha

To clean the ovens set the oven control stat to 250ºC for 30 to 40 minutes then turn off and allow to cool. Once the oven is cool all you have to do is vacuum inside the ovens!!

Exterior cleaning of the Alpha may only be done when unit is cold or just warm to touch. You can use warm soapy water or ‘Astonish’ cleaner which can be purchased through us.

Hotplates must be kept clean to ensure good operation

The Alpha Oil central heating model will run up to 160,000 BTU output.

The Alpha Gas central heating model will run up to 120,000 BTU output.

Fully pumped and vented or sealed but not gravity.

It is also well adapted for under floor heating.

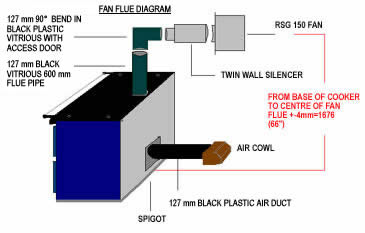

Fan Assisted Flue

The Alpha can also run on a Fan Assisted Flue. However this option is not available on the following models:

ALPHA DRY GAS

60,000 BTU OIL

60,000 BTU GAS

160,000 BTU OIL

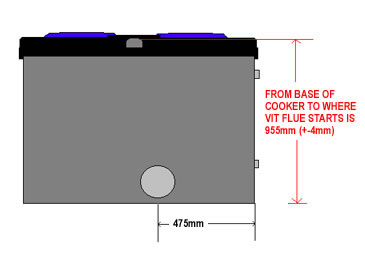

Please see below a diagram of how the fan flue can be assembled (again never start with a bend)

Building Rules & Regulations

As per the building rules and regulations customers need to supply combustion air to the appliance.

Combustion air is vital for the Alpha to work correctly and safely. It is also a British Standard requirement, which is based on heat input.

For Oil (28 Sec) you will require 5.5 cm² for each kW over 5 kW

For Example:

A 29.6 kW boiler and 16.28 kW cooker burner = 45.88 – 5 kW = 40.88 x 5.5 = 224.84 cm².

For Gas 5 cm² per kW

All combustion air vents must be low level. This means no higher than 1-2 metres above the floor.

Please see below the air gaps either side of the Alpha, which are required so that the burners can “breathe”:

| Left Hand Side* | 150mm | *Please note when positioning the cooker in a corner of the kitchen, ie, a corner unit to the right hand side, a distance of 200 mm will be required. This is to allow both oven doors to open fully. |

| Right Hand Side* | 50mm | |

| Back | 50mm |

Of course you could increase the gap required on the Right Hand Side to 150 mm so that both sides are symmetrical. Also, many of our customers have put hanging doors with slots in to fill in these gaps.

Please also note that additional high level ventilation will be required if an extractor is to be used and or tumble dryer.

If you are going to position your Alpha on an outside wall, we can supply a purpose made Air Duct to the outside to go through your wall.

What central heating system can be used to run my Alpha?

a. Fully pumped system

b. Full pressure system, un-vented hot water tank

c. Under floor heating

d. Sealed system

e. Vented conventional system

The Alpha will not work on a gravity system but you can convert this system to fully pumped system by putting in a pump on the flow.

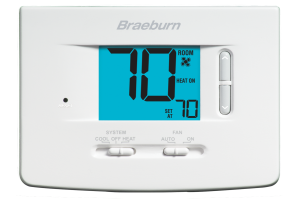

A 3-way programmer is also supplied with the Alpha so that the heating, cooking and hot water can be controlled altogether or at separate times.

Please note that the cooker will be hot when it is on. Once it is off it will slowly cool down. However, if the hot water or central heating is on and the cooker is off, the alpha will be cold.

More Technical Notes:

Power supply 220 volts, 5 amp, 50 Hz.

Gas supply minimum 22 mm gas pipe working pressure at the cooker must be 20 mb +/- 1 mb.

Oil supply 10 mm pipe normally, variations may be required according to model and pipe minimum.

Can be gravity (preferably) or two pipe system maximum lift 2.5m.

Boiler tapping:

28 mm (1½”) B.S.P – 60,000 to 100,000 models

42 mm (1¼”) B.S.P – 120,000 to 160,000 models

Design temperature:

76ºC to 78ºC at flow with a maximum differential of 11ºC between flow and return at boiler.

Flow rate 39 litres per min.

Central heating pump must be on the flow after the pump there must be a 22 mm by-pass heat sink radiator of 1.2 kW then two zone valves not a three-port valve.

Heat Source:

Burners are Ecoflam, minor one to 8 pressure jets for oil using Danfoss pumps and Landis controls.

Azur 30 and Azur 40 forced draught gas burners using Kromschroder and Landis controls.

Combustion Air

Combustion air is vital for the Alpha to work correctly and safely. It is also a British Standard requirement which is based on heat input.

For Oil:

(28 sec) you will require 5.5 cm² for each kW over 5 kW

For example:

A 29.6 kW boiler and 16.28 kW cooker burner = 45.88 – 5 kW = 40.88 x 5.5 = 224.84 cm².

For Gas 5 cm² per kW

All combustion air vents must be low level. This means no higher than 1-2 metres above the floor.

Cooking, Central Heating and

Hot Water Models

| Cooking, Central Heating and Hot Water Models | Cooking Only Models | ||

| Oil | Gas | Oil | Gas |

| Alpha 60,000 | Alpha 60,000 | Alpha ‘Dry’ Model | Alpha ‘Dry’ Model |

| Alpha 80,000 | Alpha 80,000 | ||

| Alpha 100,000 | Alpha 100,000 | ||

| Alpha 120,000 | Alpha 120,000 | ||

| Alpha 140,000 | |||

| Alpha 160,000 |

| Options: |

| Fan Assisted Flue |

| Conventional Flue |

| Domes – Cast, Chrome, Brass |

| Fittings – Chrome, Brass |

Frequently Asked Questions

Q. What is the weight of the Alpha?

A. The Alpha weighs 580 Kg.

Q. Will the boiler run under floor heating?

A. Yes, the boiler is a modern day boiler. However, the under floor heating must be installed following the manufacturer’s instructions.

Q. When heating or hot water is required will the cooker side of the Alpha have to be on?

A. No! the Alpha is totally controllable, the cooker is independent of the boiler mode.

Q. Can I run heating only, as my hot water is already catered for?

A. Yes, you do not need to have a hot water tank if this is already catered for.

Q. Can I connect straight up to my existing heating system?

A. Yes, you will need to have a heat sink radiator 1 to 1-5 kW after the pump which must be on the flow pipe from the boiler and a bye pass will need to be added just before the zone valves. All systems must be fully pumped.

Q. Can the cooker be turned off when I have finished cooking?

A. Yes, all you need is 30 to 40 minutes to allow the ovens to reach the required temperature.

Q. Can an extractor fan be installed directly above the Alpha?

A. Yes, you will have to add just a small additional high-level ventilation.

Q. Will the Alpha require a flue pipe?

A. Yes, a conventional flue “Class One” specification. Alternatively a Fan Assisted flue is available if a conventional flue is not possible in most models.

Q. Can we use an existing flue?

A. A stainless steel liner may be required in such circumstances. This must be back filled with micro fill or an equivalent.

Q. How often does the Alpha need to be serviced?

A. A full service is recommended on an annual basis for 28 Sec Oil and Gas. Twice a year for 35 Sec heating oil (otherwise known as diesel.)

Q. What is combustion air?

A. Combustion air is vital for the Alpha to work correctly and safely. It is also a British Standard requirement which is based on heat input. For 28 Sec Oil you will require 5.5 cm sq for each kW over 5.

For Example:

A 29.6 boiler and 16.28 kW cooker burner = 45.88 – 5 kW = 40.88 x 5.5 = 224.84 cm sq.

For Gas 5 cm2 per kW.

All combustion air vents must be low level. This means no higher than 1-2 metres above the floor.

Q. What is the approximate fuel consumption of the Alpha?

A. Approximate fuel consumption

The following table is based on the central heating being on for four hours in the morning and six hours in the evening. The cooker fuel consumption is based on the cooker being on two hours in the morning, two hours mid-day and two hours in the evening. The boiler heating system must be balanced within 12°C between the flow and return pipe.

| Model | Litres per hour |

| 60000 BTU | 1,65 |

| 80000BTU | 1,73 |

| 100000BTU | 2,19 |

| 120000BTU | 2,66 |

| 140000BTU | 3,11 |

| 160000BTU | 3,62 |

| COOKING ONLY BTU | 1,29 |