Application

AKO Temperature Regulators are suitable for the stabilization of temperatures of media (e. g. water, oils, etc.)

and are even applicable as dividing units or mixing valves. Depending on their construction they are distinguished

by their low need of maintenance, particular operating convenience and resistance to pressure. A replacement of

inner parts is possible on the spot without having to remove the regulating valve from the piping. A faulty

assembly can be excluded. The temperature regulators could be assembled in each fitting position.

Function

AKO Temperature Regulators are being equipped with easily replaceable internal wax-filled thermostats that

absorb the temperature of the medium surrounding them at the measurement point namely into expansion and

thus a change in path or length (the valve stroke). AKO Temperature Regulators do not require any auxiliary

energy. At rising temperature and on excess of the opening temperature, the tube slider is being lifted off on the

valve seat and opening path A to C, with the path A to B locking simultaneously in the same ratio. The change is

being performed in proportion to the change of temperature of the passing medium.

Technical Data:

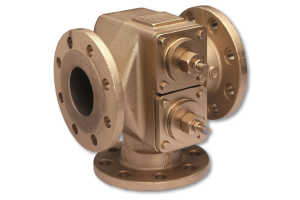

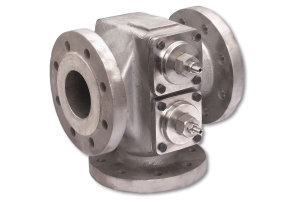

| Body Material | 1.4308 / CF8M (DN150) |

| Inner Parts Material | SS / Brass |

| Thermostat | 237.0120-xxx-0 |

| Sealing Kit | NBR |

| Operating Pressure | up to 16 bar |

| Adm. Differential Pressure | up to 16 bar |

| Nominal Pressure | PN 16 |

| Connection Flange | EN 1092-1 type B |

Deliverable sizes: 40, 50, 80, 100, 150 mm